Permanent QR code marking on plastic products during injection process.

QR code, Data matrix mold insert

■For plastic injection mold

Uratani produces QR code, data matrix injection mold component. This is cost effective and environmentally friendly method of marking QR code on plastic products. The mark is permanent and won't wear off. The insert is replaceable so QR code can be changed for every lot. We sell our product globally.

Features

Installation cost is low

If you want to mark on plastic products, only a little repair of a mold is necessary.

Additional marking time is zero

Unlike printed materials or laser marking, additional effort of marking is zero.

Permanent marking

QR code is directly marked on a plastic product. It won't wear off like stickers.

QR code is changed easily.

QR code insert can be replaced easily from the mold.

Benefits

① No need for putting QR code stickers Won't wear off Permanent marking

Putting QR code stickers is necessary for traceability especially in a factory. It is time consuming for factory workers. QR code insert helps marking QR code during injection process.

Putting stickers is time consuming

and wear off easily

Permanent marking on a plastic product

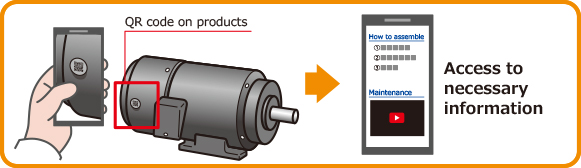

② Provide information of a product through website

When customer wants additional information (such as maintenance method, assembly, caution, warning, EC sites for additional parts etc… ), QR code helps to provide those URL. It improves customer satisfaction and reduce customer calls.

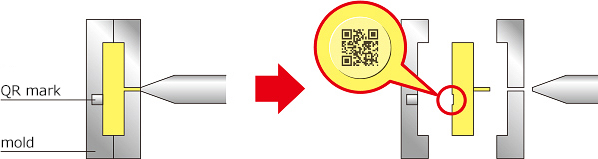

Marking method

QR code insert is inserted in the mold for marking during plastic injection process.

Application

We recommend to use QR code reader "QRQR"

QR code reader "QRQR" ▶We have supplier globally to fulfill your request.

*QR Code is registered trademarks of DENSO WAVE INCORPORATED in Japan and in other countries.